High Frequency PVC Door Fly Welding Machine

Application:

For welding PVC curtain, clear curtain, PVC folder, PVC page, PVC bags...

Mainly used for family hotels, restaurants, food processing plants, fresh processing centers, beverage processing plants, pharmaceutical plants, a variety of plants by insect repellent, a variety of health and safety areas.

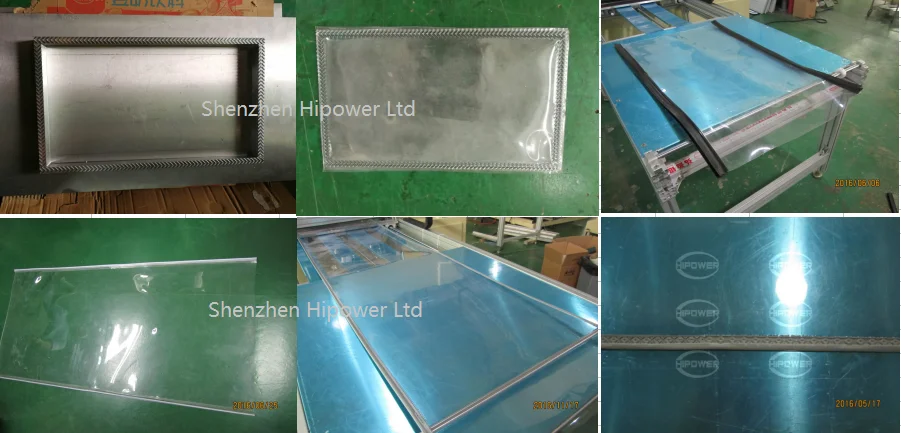

samples:

Function:

1. Feeding, pushing material is optional, speed is under control

2. The machine has heating and flatting devive, digital counter

3. Transmission system adopts imported wear resistant resin material

4. No scratch sheets

5. Photoelectric sensor, synchronous collection rack, the control precision

Parameter

|

model |

HR-8000G |

|

HF power |

8KW |

|

Power frequency |

3P 380V 50/60Hz or customize |

|

frequency |

27.12MHz |

|

Input power |

15KVA |

|

rectifier |

SILICON DIODE |

|

Oscillation tube |

7T69RB |

|

Maximum pressure |

20T |

|

Pressure mode |

Air hydraulic |

|

Maximum distance of eletrodes |

200MM |

|

Moving distance of electrodes |

100MM |

|

Upper electrode |

500*700 mm |

|

Down electrode |

600*800 mm |

|

Temperature range |

30 to 200 Adjustable |

|

Welding time |

0.01~9.99S Adjustable |

|

productivity |

Equal or less 5000times/8h |

|

Net weight |

3.6T |

| Gross weight | 3.8T |

|

Overall dimension |

9250*1850*2200 mm |

Excellence of Equipment:

1. Spark suppressor: When sparks, the special electronic circuit works and cuts off the high frequency to suppress spark automatically and minimize the damage of electrodes and materials. Also. The warning lights works.

2. Prevention for radio interference device: Equipped with frequency stabilizer and high-frequency magnetic leakage suppressor. This device eliminates the leakage of radio waves to interfere other electronic devices such as TV, radios, etc..

3. Safety devices: When the current exceeds the limit value, the overload current relay works to protect oscillator and rectifier automatically. Frequency deviation caused by the improper operation is also prevented.

4. Easily adjustable device: Output power can be adjusted according to electrode size and material thickness. Other control devices and special electronic circuits can reduce required welding time and improve the machine's productivity.

Our advantage:

Our company insists the quality first, customer supreme idea, our superiority: One year and so on maintenance, three months and so on exchange guaranteed, life-long service

service

1. Recommend equipment of top choice based on your requirements for product;

2. Examining mold drawings on your behalf to confirm optimum structure size meeting high frequency process;

3. Providing assistance in manufacturing and modifying tools;

4. Free door to door service for installation and debugging;

5. Professional training for operators;

6. Our engineering instruction will guarantee your productive manufacturing of top-quality products.

7. Available within 24hours within Guangdong Province and 48hours beyond the province;

8. Our regular return visits ensure continuous improvement of our service quality.

Where Are our Customers:

Our products are mainly exported to Asia, North America, South America, Europe and Africa, and etc....

Our company are verified by SGS, BV. and our machines are with CE certificates.

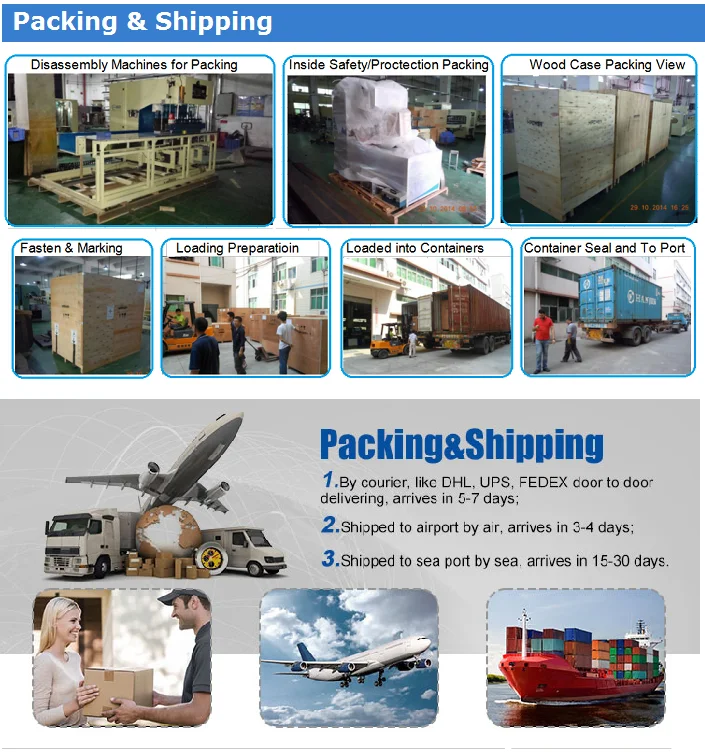

We use Ply-wood case for packing machines, it will meet export standard like safty, protection requirment

and durable performance in long time shipping by sea or by air.

We can provide non-solid wood packing decleartion, our packing no need fumigation.

a) Customer's site installation, training & maintenance available

d) Recommend equipment of top choice based on your requirements for product;

e) Examining mold drawings on your behalf to confirm optimum structure size meeting the requested process;

f) Providing assistance in manufacturing and modifying tools;

g) Our engineering instruction will guarantee your productive manufacturing of top-quality products.

Questions 07. How Do You Pack the machines

RE: Our machines will be packed into wood case, (we will process the wood case and make sure it is exporting standard, and no need addtional fumugation)

Questions 08. Is it difficult to install the machine ?

RE: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine;

you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get install videos, and install instructions from us.

It will be an ABC thing to install machines at your side.

Questions 09. Does the machine power voltage meet buyers' factory power source?

RE: We can make machine with voltage like:

frequency: 50 - 60HZ Phases: single phase / 3 phases

Voltage: 110V / 220V / 380V/ 415V/ 440V / On request

Questions 10. Could you make die / mould for me, if I buy machine from you?

RE: We design and make moulds up to product sample or drawings, we charge the mould price at facory cost price.

Contact: Andy Lu

TEL NO.: +86 135 9014 6525

Whatsapp: +86 135 9014 6525

Web: www.hipowerweld.com

www.hi-pwr.com

Factory address:Zhongrui Industrial Park,Xintian,Guanlan,BaoAn Dist.Shenzhen,Guangdong Province,China.

Write a customer review0 Comments

No Comments