- Product Display

- Product Display > Customized Equipments

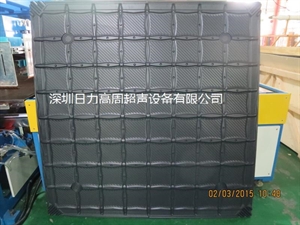

Large H.F Machine for cooling tower packing

| Model: | HR-50KW |

| Scope Of Application: | applied for welding large pvc sheet, cooling tower cooling plastic sheet, cooling tower packing,cooling tower PVC packing, industrial cooling tower packing, Drenching PVC sheet, Marley cooling tower packing, PVC drenching sheet, cooling tower PVC drenchi |

| Features: | 1. CE rated, with CE certificate2. Double heads, 4 sliding welding stations3. Pneumatic mould hanging structure available4. Automatic sliding table, table size 2000*2200mm5. Imported Japan Toshiba tube installed,6. 5557 anti spark installed |

Large H.F Machine for cooling tower packing

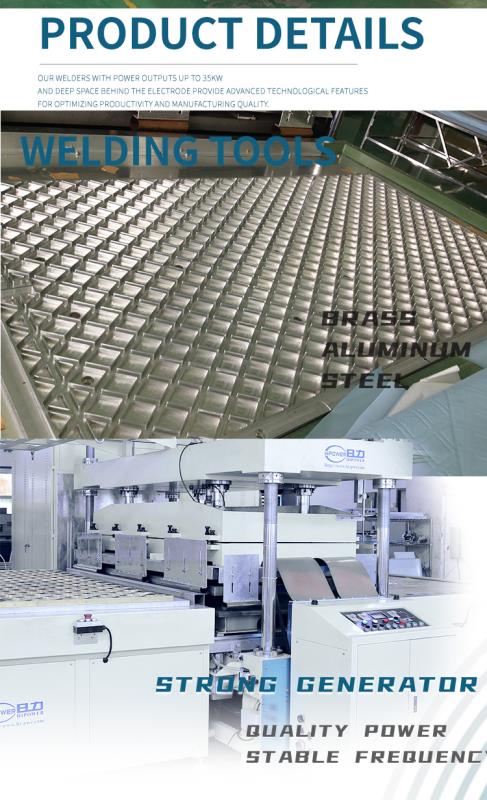

I. Machine Features

1. CE rated, with CE certificate

2. Double heads, 4 sliding welding stations

3. Pneumatic mould hanging structure available

4. Automatic sliding table, table size 2000*2200mm

5. Imported Japan Toshiba tube installed,

6. 5557 anti spark installed

7. Lower working table with optional heating function.

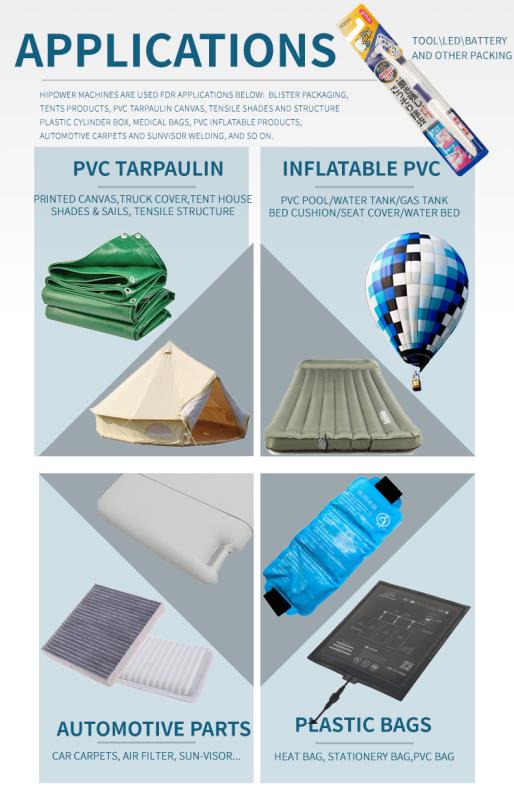

Application:

applied for welding large pvc sheet, cooling tower cooling plastic sheet, cooling tower packing,cooling tower PVC packing, industrial cooling tower packing,

Drenching PVC sheet, Marley cooling tower packing, PVC drenching sheet, cooling tower PVC drenching sheet, cooling tower PVC drenching packing.

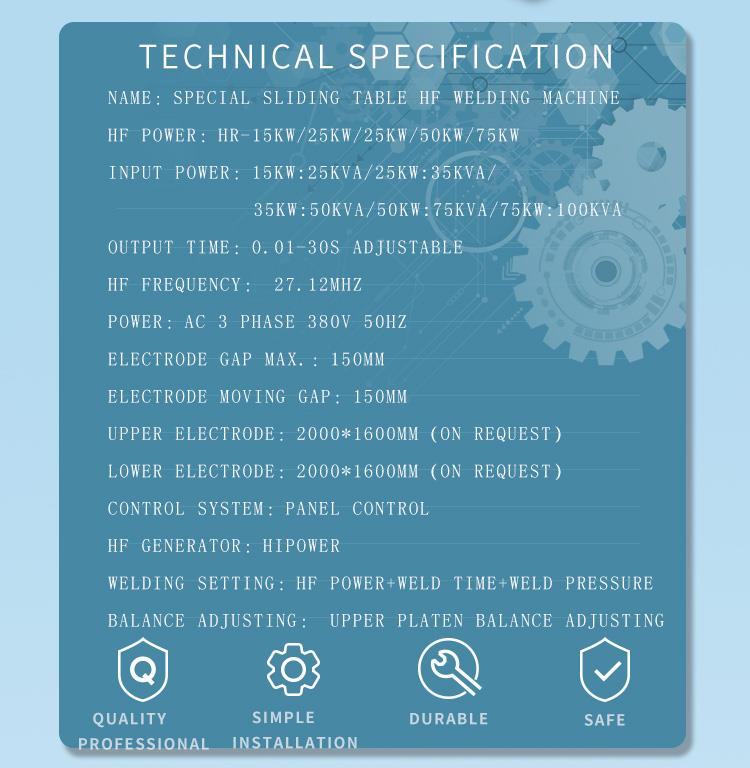

Technical Specifications:

Model: HR-50KW

Output Power of Generator : 50KW

Anti-Spark System: 5557

Voltage : 380V 3Phase

Frequency: 13.56 MHZ

Input power: 70KVA

Rectifier: SILICON DIODE

Oscillation tube: 9T64A

Max pressure: 2000kg

Operation mode: Peumatic

Max gap of electrodes: 150mm

Size of active horn: 150mm

Upper Electrode (W*H*L): 2000*2200mm

Size of Work Table (L*W): 2000*2200mm

Welding time: 1- 10S

Net weight: 22 Tons

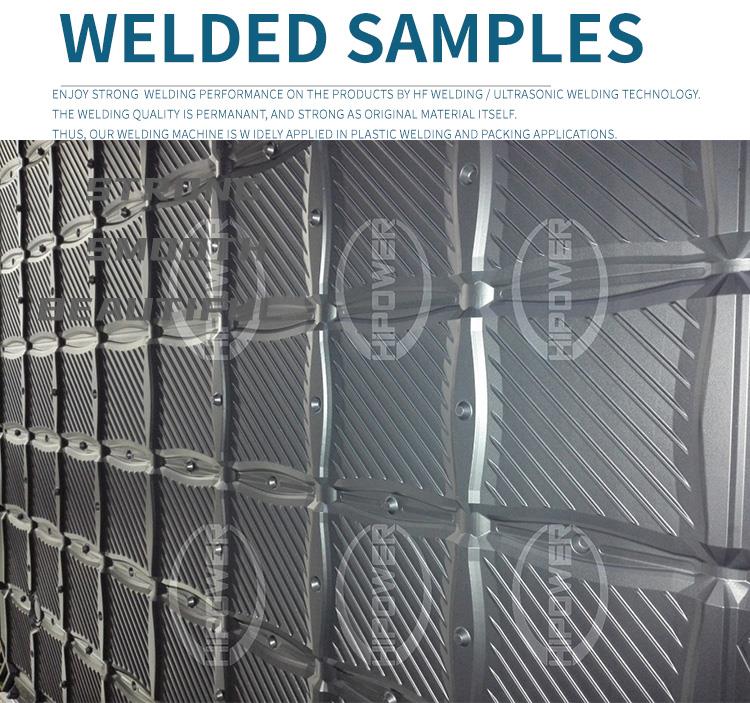

1.Machine working table size: 2000*2200mm ,convenient in large area welding.

2.The 4 working station can feed with different mould size, to make full use of one machine

3. Firmly weld ,be well meeting with materials of thick or thin.

4. Adopting high sensitive anti sparkle device NL5557 to avoid damaging the mould.

5. High quality imported apparatus, Facilitate large-scale continuous connection.

6 .European standard high-frequency oscillatory square box, more reliable and Stable in output.

7.All sizes available related machines made by request

Previous Products: HR-8KW-30T High frequency puff/foam welding&cutting machine

Next Products: HR-8KW-2AC high frequency welding machine for leather embossing