- Product Display

- Product Display > Ultrasonic Welding Machine > Customized ultrasonic welding machine

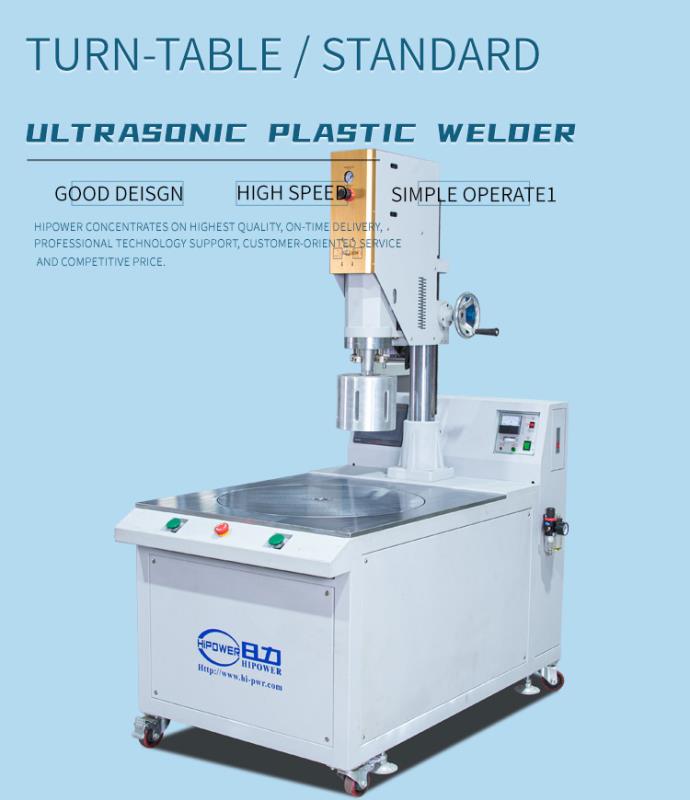

HC-2020D-4AC Turntable Ultrasonic Welding Machine

| Model: | HC-2020D-4AC |

| Scope Of Application: | Applied for ultrasonic welding of ABS,PE,PC,PS,PVC,PP,ABS and PC complex ,acrylic etc. |

| Features: | The straight line guide bearing, the precise matching deviceThe horizontal zoom type structures of four corners allocate that the board four corners at bottom can transfer the standardJapan HuangPai steel becomes a ware, and the horizontal zoom type s |

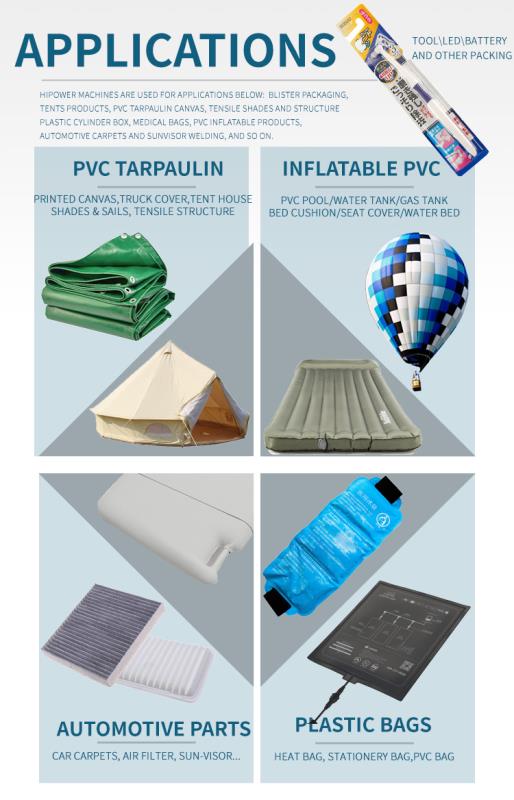

Applied range of Ultrasonic welding machine:

Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc. For example: disposable transfusion filter, blood plasma whizzer, valve bag, plastic wine bottle cap, dish washer waterwheel, plastic toys, car lamp, plastic fake bait, charger shell and mobile hanging drop welding, disposable lighter shell welding etc. Besides: car door plaque welding, car motormeter welding, car lamp car mirror welding, sun visor welding, car inside accessories welding.

Product Introduction

Hipower 20KHz Ultrasonic Welding Machine Applied to

ultrasonic welding: Ultrasonic Vibration transmit the energy via welding horn to plastic workpiece surface, generating localized hyperthermia to melt the plastic surface. Under pressure of the ultrasonic welding machine, make 2 pieces of plastic workpiece to weld, get a good-looking and stable entire product.

Ultrasonic embedding: Putting screw, nut or other metal into plastic workpiece.via transmitting ultrasonic energy to the metal. After highly speed vibration produce heat, make the metal directly embed into the plastic workpiece under ultrasonic machine pressure.

Ultrasonic riveting: To make metal and plastic or 2 pieces of different materials plastic weld together, you can use ultrasonic riveting, to make the welding product not easily brittlemen, elegant looking and stable.

Ultrasonic spot welding: using small horns on ultrasonic machine, to weld 2 plastic workpieces on many spots, or whole row dentation horns directly press on 2 pieces of plastic, to get the ultrasonic spot welding effect.

Ultrasonic forming: use ultrasonic machine to melt plastic workpiece very soon, when the plastic solidify, the metal or other material plastic will become firm.

Ultrasonic cutting: using special design of ultrasonic welding horn or welding board, via ultrasonic transmitting, to get the effect of cutting the cloth or plastic.

Ultrasonic Plastic Welding Machine Theory: Transmitting 50/60 hz electric current into 15, 20, 35 KHz electric power via ultrasonic generator. The high frequency electric power transmitted into same frequency mechanical movement, then the mechanical movement transmitted to ultrasonic horn via amplitude modulator. The horm transmit the ultrasonic vibration energy to the weld part of the workpiece. In this part the ultrasonic vibration energy changes into heat via friction, to melt the plastic. Ultrasonic plastic welding time and pressure of horn is adjustable. It depends on transducer and amplitube modulator.

Character

The straight line guide bearing, the precise matching device

The horizontal zoom type structures of four corners allocate that the board four corners at bottom can transfer the standard

Japan HuangPai steel becomes a ware, and the horizontal zoom type structure of lasting durable horn allocates that the board four corners at bottom can dive flatly

Frequency modulation and the frequency automatic equalization circuit

Debug the soft Boot circuit of equipment, and avoid damaging the mould

Squre column and column airframe structure is optional

Before-sales Service

Our free technical assistance is available to you from now on:

1.Recommend equipment of top choice based on your requirements for product;

2.Examining mold drawings on your behalf to confirm optimum structure size meeting ultrasonic process and high frequency process;

3.Providing assistance in manufacturing and modifying tools;

4.Sample for welding.

During-sales Service

1.Punctual deliver of equipment as per Contract;

2.Free door to door service for installation and debugging;

3.Professional training for operators;

4.Our engineering instruction will guarantee your productive manufacturing of top-quality products.

After-sales service

1.Available within 24 hours within Guangdong Province and 48 hours beyond the province;

2.Our regular return visits ensure continuous improvement of our service quality.

The manufacturer has right to modify the design and parameter without prior notice

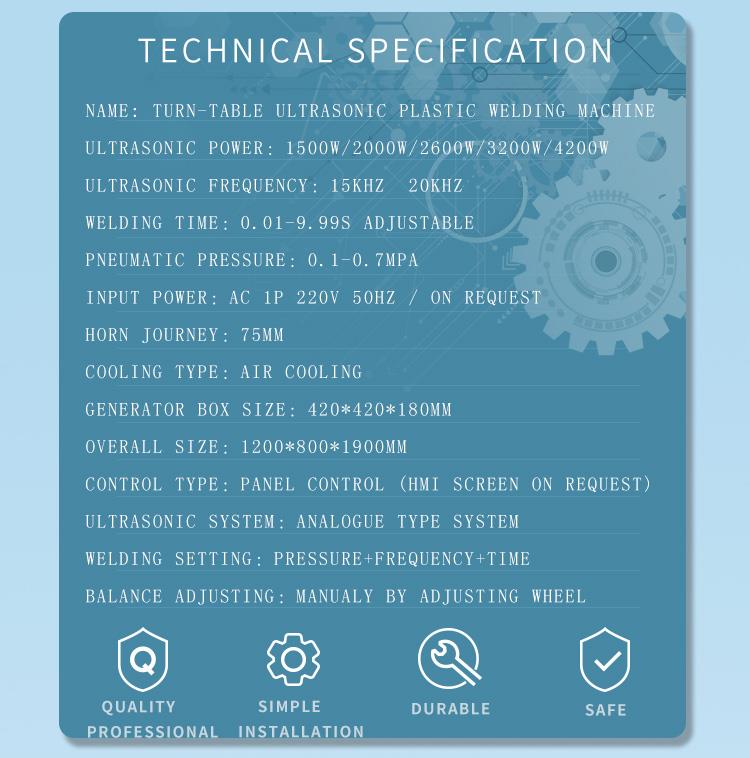

Technical parameter:

|

Model |

HC-2020D-4AC |

|

Power |

2000W |

|

Voltage |

220V |

|

Frequency |

20KHZ |

|

Max Input power |

1.2KW |

|

Stroke |

70mm |

|

Vibration system |

Auto-stimuilating |

|

Output time |

0.1-99s |

|

Range of pressure |

1-7bar |

|

Air compressor |

1HP |

|

Net weight |

290KGs |

|

Gross weight |

340kgs |

|

Overall dimension |

2.2CBM |

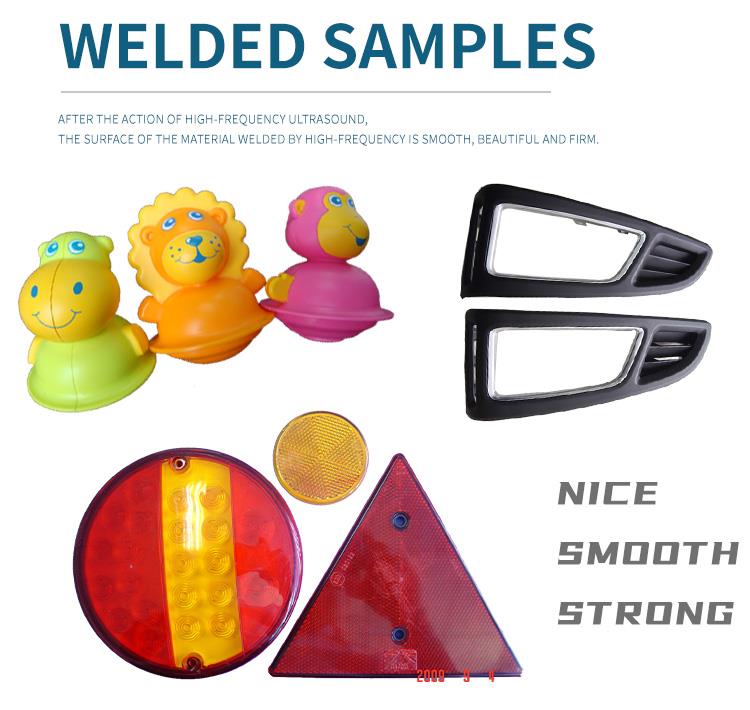

Sample view:

Previous Products: HC-1520 Ultrasonic plastic welding machine for PVC

Next Products: HC-4215D-4AC ultrasonic cylinder bottom welding machine