- Product Display

- Product Display > Refrigeration Dryer > Water-Cooled Refrigeration Dryer

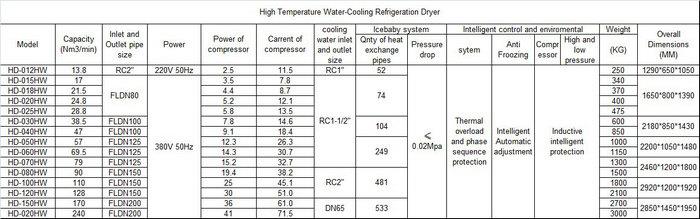

HD Series High Temperature Water-Cooled Refrigeration Dryer

| Model: | HD-0040HW |

| Scope Of Application: | For Air Compressor to dry air |

| Features: | 1.Enlarged heat exchange flow channel 2.ICEBABY heat exchange device adopting vertical type 3.Multiple baffles4.Dual-stainless steel screen gas-liquid separator5.Surplus Evaporation Area 6.Top-laid Fan |

Parameters

1.Temperature of operating environment: 2℃≤lowest temperature, highest temperature≤56℃

2.Inlet temperature of compressed air: rated temperature≤85℃

3.Designed pressure corresponding to processing capacity: 0.7Mpa

4.Maximum bearing pressure of preposed evaporator shell: ≤1.3Mpa

5.Pressure dew point: +2℃~+10℃ (atmospheric dew point: -23℃~-17℃)

6.Cooling Conditions: soft water for industrial use. Water pressure 0.3~0.5Mpa;Water Temperature ≤32℃. Water supply capacity 0.25t/H*Nm3/min.

7.Substances to be avoided: avoid the strong acid and alkali suspending enviroment;avoid the ammonia gas (ammonia molecule) suspending enviorment and prevent strong acid and alkali and ammonia gas entering the core part of evaporator.

8.Notice on pipeline installation: the refrigeration dryer shall be installed behind the buffering air cylinder pipeline (when it’s directly installed behind the air compressor, the pulse of the air compressor may cause damage to the inner core elements of evaporator and even cause safety accidents). And the front of refrigeration dryer shall be at least equipped with one pipe filter.

9.Installation environment: no sunshine, no rainwater, hard foudation,no dust and flying willow catkins; and it must be installed behind the buffering gas reservior pipe.

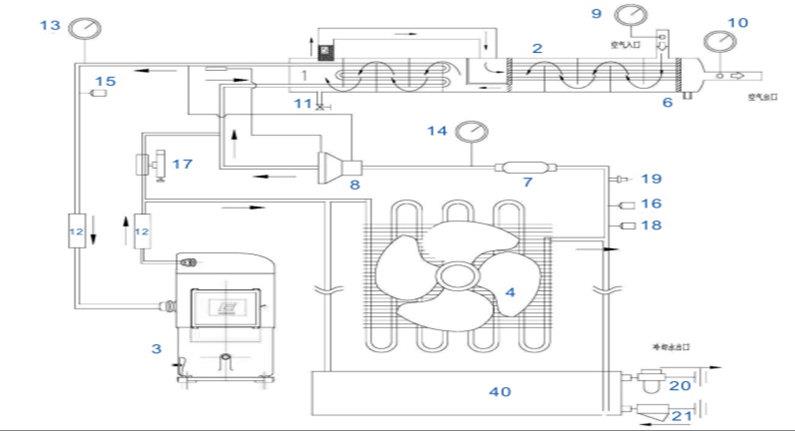

Structure Flowchart of Refrigeration Dryer

|

1. Evaporator 2. Pre-cooling temperature recovery device 3. Compressor 4. Wind condenser 40. Water condenser 5. Steam-water separating device 6. Sewage disposal 7. Dry filter |

8. Throttling device 9. Air inlet 10. Air outlet 11. Electric drain valve 12. Lightning protection hose 13. Low-pressure refrigerant meter 14. High-pressure refrigerant meter |

15. Low-pressure charging valve 16. High-pressure protection switch 17. Refrigerant bypass valve 18. Pressure controller 19. High-pressure charging valve 20. Water control valve 21. Drain filter |

Description of compressed air flow:

High-temperature and wet compressed air enters the (2) pre-cooling temperature recovery device (ICEBABY) from the (9) air inlet, and implements heat exchange with the cooled low-temperature compressed air flowing through the evaporator to release part of heat energy and remove remaining water content. At this time, the compressed air after level-1 cooling and dewatering enters the (1) evaporator and implements heat exchange with evaporator to remove the remaining water content; then, the (5) steam-water separator will separate water content from the compressed air, and liquid water will be drained through the (11) electric drain valve; but the low-temperature and dry compressed air will be back to the (2) pre-cooling temperature recovery device to absorb the high-temperature compressed air heat at the inlet position to make its temperature recover to the ambient temperature, and then the compressed air will be discharged through the (10) air outlet.

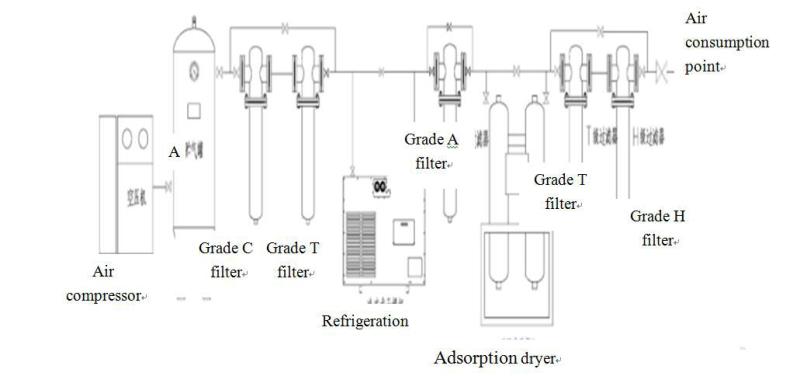

Configuration of Compressed Air Cleaning System

It’s necessary to configure the equipment as the followed flowchart. Both the refrigeration dryer and adsorption dryer shall be equipped in pipeline behind air cylinder. Moreover, the adsorption dryer and various filters shall be selected as technological requirements of air use.

The pipeline in front of the adsorption dryer must be equipped with one Grade T and Grade A filters respectively at least.

For any configuration questions, please consult our technicians and designers.

System Configuration Flowchart

Coolers and air tanks behind the system shall be selected as above configurations.

Key Points of Design

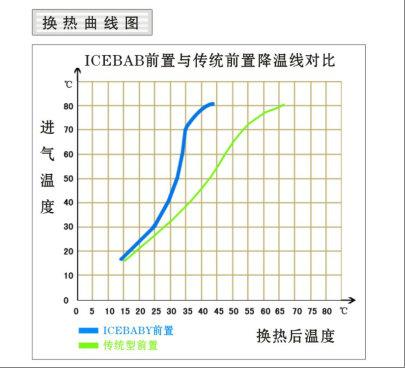

Heat Exchange Curve

The higher cooling ability does ICEBABY have, the lower the temperature of compressed air to the evaporator of refrigeration dryer is. Lower loads on refrigeration system could ensure the pressure dew point of the refrigeration dyer better.It’s known from left figure that the cooling curve of ICEBABY preposed type is superior to traditional one. When the inlet temperature is 80℃, the temperature of compressed air will drop to 43.5℃ after flowing through ICEBABY preposed type, while the temperature of compressed air could only drop to 66℃ after flowing through traditional preposed type. It’s clear that the cooling performance of ICEBABY is more than twice higher than traditional ones.

Test condition:

Rated displacement of air compressor: 3.6m3/min

Rated pressure of air compressor: 0.66~0.75MPa

Suction temperature of air compressor: 6℃ + 0.4

Ambient temperature of refrigeration dryer: 40℃ + 0.5 (after heating)

Refrigeration ability of compressor: 2.7KW

Use the same units and the same refrigeration components.

Air inlet heating device will be installed before the refrigeration dryer unit.

Simulate the inlet temperature for test.

Four Guarantees—Ultra-strong Dewatering Effect

1.Enlarged heat exchange flow channel

When the gas flows into the heat exchange cylinder, the heat exchange time extends and full and comprehensive heat exchange is realized due to the volume expansion and slowdown of flow speed. Moreover, the condensing time of condensed water prolongs so that the water could separate from the gas fully.

2.ICEBABY heat exchange device adopting vertical type

The new type bare pipe-guided cold-heat alternating ICEBABY is of vertical type and fully utilizes physical principles. Under the effect of earth gravity and whirlwind centrifugal force, dry finished gas flows upward, while the condensed water flows to the bottom, which realizes excellent gas-liquid separation effect and guarantees the overall dewatering effect.

3.Multiple baffles

The evaporator and ICEBABY are installed with multiple built-in baffle plates, and meanwhile, the water filtration device is equipped with baffle plate as well so as to slow the flow speed down, prolong the heat exchange time, effectively utilize interception effect and bump effect to achieve much thorough dewatering.

4.Dual-stainless steel screen gas-liquid separator

Under the effect of interception effect, inertial effect, diffusion effect and bump effect, the gas-liquid separator ensures full water-gas separation; and further guarantees the dew point of finished outlet air due to the downward separation procedure design.

Key Points of Design/Product Features

A.Surplus Evaporation Area

The evaporation area tested under limiting conditions for times based on optimized design matches with the processing capacity of the system perfectly on the basis of enough design surplus, guarantees sufficient evaporation of refrigerants in the evaporator and controls the superheat of the refrigeration system perfectly. Besides, the refrigerating capacity of the compressor is fully utilized to realize energy-saving, high-efficiency and steady running.

B.Top-laid Fan

Such design conforms to natural phenomena. According to the principle of hot gas rising, the high-temperature air exhausted from the cooling fan on condenser is discharged from the top so as to promote the condensation efficiency of the condenser to the largest extent. Meanwhile, the cold air is sucked from sides and the hot air is exhausted out of the crate directly from the top. In this way, the flow direction is single and eliminates disordered flows in the crate completely. Meanwhile, such design also eliminates the mutual disturbance during operation so that it’s able to install equipments in a concentrated manner.

Perfect Effect from Perfect Design

1.Steadier performance

Scientific and reasonable structure improves the operating efficiency; and ultra-large evaporator and 0.6MM inner grooved copper pipe with electrophoresis treatment ensure no leakage, safer and steadier operation and reduce unnecessary maintenance.

2.Much thorough dewatering

The multiple separation effects, enlarged heat exchange flow channel, vertical type ICEBABY, built-in multiple baffles and the multiple-procedure design of gas-liquid separator with stainless steel screen ensure ultimate dewatering effect.

3.Higher cost performance

The scientific and perfect design and optimal configuration enable HS series refrigeration dryers to be a type with distinct cost performance.

4.More trusts from users

You may rest assured on Hipower products due to their stability, feel ease on Hipower products owing to their high efficiency and energy conserve.

Previous Products: HZ-400 vacuum package machine

Next Products: HD Series High Temperature Air-Cooled Refrigeration Dryer