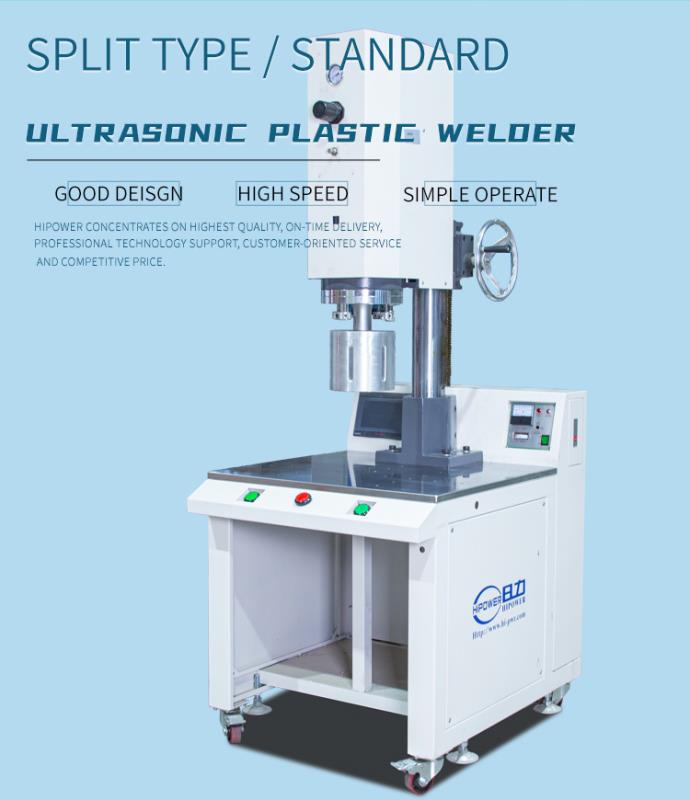

- Product Display

- Product Display > Ultrasonic Welding Machine > Standard Ultrasonic Welding Machine

HC-4215 High Power Ultrasonic Plastic Welding Machine

| Model: | HC-4215 |

| Scope Of Application: | Applied for ultrasonic welding of ABS,PE,PC,PS,PVC,PP,ABS and PC Complex, Acrylic and Relatives |

| Features: | IC circuit precision control, automatic overload protection systemAdopting digital switch, 1/100 precision re-set controlAdjustable horizontal level, easy control welding hornHigh Q value transducer, optimized output |

HC-4215 High Power Ultrasonic Plastic Welding Machine

Characters:

IC circuit precision control, automatic overload protection system Adopting digital switch, 1/100 precision re-set control

Adjustable horizontal level, easy control welding hornHigh Q value transducer, optimized output

Have resonant frequency when the load, unload, without adjustment for the frequency of welding horn

Square column and column airframe structure is optional, the straight line guide bearing, the precise matching device

Using the turbine rotation to adjust the machine movement, which is better than normal

Adopting Japan HuangPai brand alloy steel to keep frequency strong and stable

Celebrate itself durability for adopting USA aviation standard 7075¡¢6064 Aluminum alloy

The electronic components are imported from Italy, Japan, American, South Korean, Taiwan etc.directly

All in one high capacity machine, applied for high precision of welding workpiece

Automatic protective device, which is optional

High power machine, which is applied for Large workpiece

Ultrasonic Plastic Welding Machine Theory:

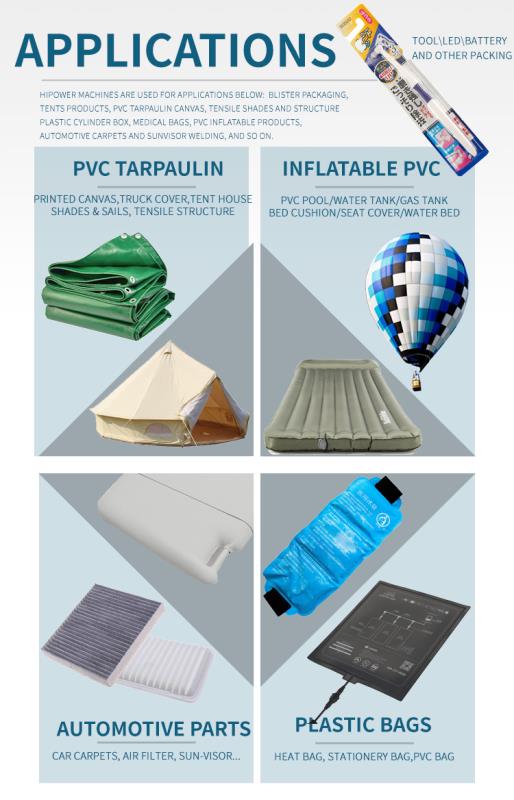

Transmitting 50/60 hz electric current into 15, 20, 35 KHz electric power via ultrasonic generator. The high frequency electric power transmitted into same frequency mechanical movement, then the mechanical movement transmitted to ultrasonic horn via amplitude modulator. The horm transmit the ultrasonic vibration energy to the weld part of the workpiece.

In this part the ultrasonic vibration energy changes into heat via friction, to melt the plastic. Ultrasonic plastic welding time andpressure of horn is adjustable. It depends on transducer and amplitube modulator. Applied range of Ultrasonic welding machine: Widely used in aviation, boats, cars, electrical appliance, package, toys, electric, medical, auto parts, fishing and textiles etc.

For example: disposable transfusion filter, blood plasma whizzer, valve bag, plastic wine bottle cap, dish washer waterwheel, plastic toys,

car lamp, plastic fake bait, charger shell and mobile hanging drop welding, disposable lighter shell welding etc. Besides: car door plaque welding,

car motormeter welding, car lamp car mirror welding, sun visor welding, car inside accessories welding.

|

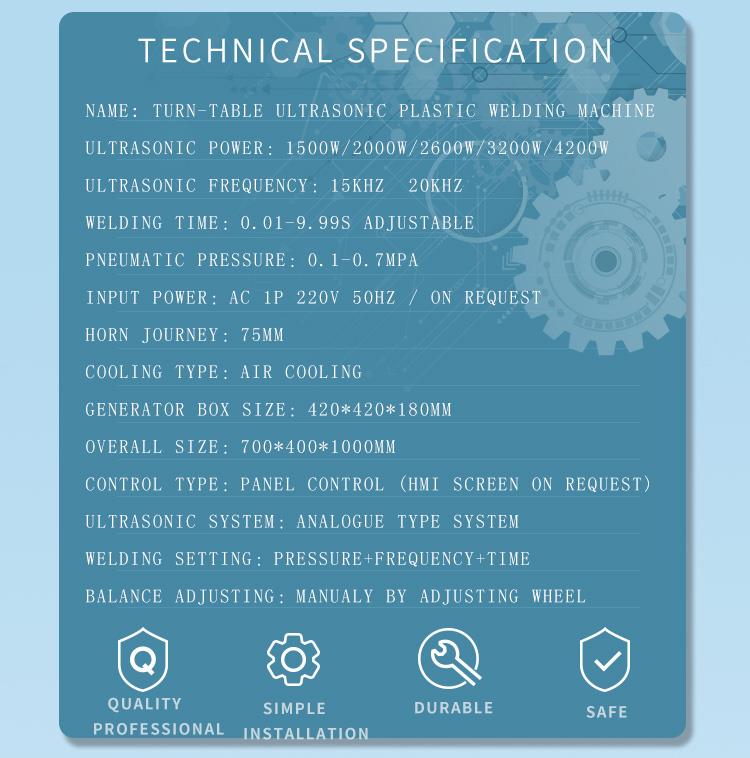

Model |

HC-2615 HC-3215 HC-4215 |

|

Input power |

2600w 3200W 4200W |

|

Frenquency |

15KHZ |

|

Input voltage |

220V |

|

The Max Input Power |

1.2KW 1.9KW 2.3KW |

|

The moving distance of active horn |

70mm |

|

Oscillation system |

Auto-stimuilating |

|

Output time |

0.1-99S |

|

Pressure |

Pressure bound 2-7bar |

|

Welding area |

∮200mm ∮220mm ∮250mm |

|

Compressor |

1HP-2HP |

|

NET |

110kg 110kg 115kg |

Previous Products: HC-3215 ultrasonic plastic welding machine

Next Products: HC-2615 PLC ultrasonic plastic welder with CE